What is “State of Health” (SoH)?

State of Health (SoH) is a measure of a battery’s performance in the present relative to that at the beginning of its life. There are different definitions of ‘performance’ - some define performance in terms of battery capacity, energy, power or internal resistance. There is no standardised definition, leaving things open to interpretation. Each manufacturer adopts their own definition of SoH which can create a confusing landscape for consumers looking to purchase used EVs when relying on these numbers in isolation.

What is on-board SoH?

Most electric vehicles will calculate their own SoH using the car’s Battery Management System (BMS). This is a little computer located either inside the battery or close by, for monitoring the pack and ensuring that everything operates correctly. Values calculated by cars themselves are normally retrievable via the car’s On-board Diagnostic (OBD) port. Manufacturers do not disclose the inner workings of their SoH calculations - this is proprietary information and remains a kept secret. This lack of transparency means that consumers are left in the dark about the true accuracy of the manufacturer’s calculations.

Why should consumers be wary of onboard values?

In addition to the lack of standardisation and transparency, there are several known quirks of onboard SoH values that mean consumers should avoid relying on these values in isolation when making purchasing decisions.

Estimates at best

The computational power and data storage capacity of most BMS systems is limited, meaning any intelligent monitoring of the battery is restricted. Furthermore, the number and placement of sensors within the pack is not dense enough to facilitate sufficient SoH monitoring. From what is known publicly of BMS SoH monitoring algorithms, most manufacturers will try to extrapolate data gathered in a laboratory from individual li-ion cells, to a full pack with several thousands of cells, modules, circuitry and bus bars. These models don’t scale accurately unless there’s sufficient monitoring and computational power at the pack level - none of which are present inside modern EVs.

Fixing to 100%

Certain manufacturers are known to lock their SoH readings at 100% for extended periods of time which masks underlying degradation. It’s thought that manufacturers do this to burn through a capacity buffer meaning that the performance of the vehicle doesn’t change over this time period even though the battery degrades. This is deceiving because it masks the actual degradation occurring inside the pack leaving these packs more susceptible to battery drop off in the future. This is best explained by looking at a typical battery degradation curve.

After an initial settling in period, most of a battery’s lifetime is spent degrading linearly, up until what’s referred to as the kneepoint. This is where the chemistry inside the battery takes a turn for the worst and the performance drops off suddenly. Manufacturers who lock their batteries to 100% SoH for long periods of time, risk encountering sudden battery drop off without sufficient warning.

Over-the-air software updates

Since most EVs are connected to the internet, manufacturers are able to push updates remotely. These updates apply to both the infotainment systems as well as the onboard computer systems like the BMS. There are several documented cases where manufacturers have pushed OTA updates in an attempt to improve on-board battery health calculations. These updates have resulted in battery health values increasing by up to 10 percentage points after the new software is installed.

Environmental conditions

Cold winters are known to distort SoH readings. Cell data is collected in the test laboratory at distinct temperatures for SoH calibration. Once a battery is taken outside of these calibration temperatures (e.g. in extremely cold conditions), the models break down and the results become less accurate.

Recalibration

Certain battery packs can recalibrate their on-board SoH readings via a slow charge from nearly empty. This has been known to change the on-board SoH value by as much as 5%, from just a single slow-charging session. This highlights the tamperability of these values - knowingly or otherwise.

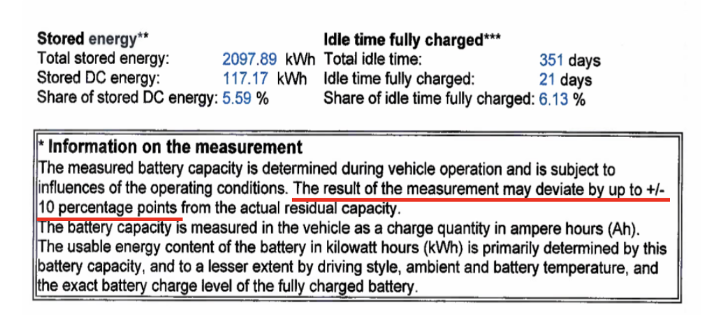

Manufacturer disclaimers

Because deriving a single, precise battery-health percentage from BMS data alone is technically fraught, most manufacturers attach sweeping caveats to the results they issue at dealerships and service centres. A typical report for Manufacturer X, for example, carries a ±10 % accuracy disclaimer, while reports for another manufacturer round capacity to the nearest 5 %. These margins underline the inherent difficulty of quoting manufacturer SoH to a single percentage point.

Using on-board diagnostic (OBD) logs from a cohort of vehicles built by Manufacturer X, we charted each battery’s reported State of Health (SoH) against its odometer reading. We surrounded every SoH point with a ±10-percentage-point envelope—the tolerance the maker quotes in its own technical notes.

Graph of onboard OEM SoH vs mileage

The combined envelopes form a single, dense shaded band that extends unbroken from first registration to beyond 127,000 miles. To highlight the implication, we added a straight black horizontal reference line: it passes through the entire shaded region, meaning that—once the declared ±10 pp uncertainty is acknowledged—any SoH value between “nearly new” and “approaching warranty threshold” (100k miles) is statistically plausible at virtually every mileage.

In practical terms, the on-board SoH figure offers little decision-making value; its published accuracy caveats are wide enough to mask the very degradation consumers and fleets are trying to measure.

Why is this not regulated?

Regulation of battery health is due to come into play as part of the Euro7 regulation and UNECE Global Technical Regulation (GTR) 22. This regulation sets out a standardised definition of battery health as well as the ways in which it will be tested, monitored, and displayed. The tolerance of accuracy set out in these regulations provides a ±5% leeway for the manufacturers, further exemplifying the challenges in accurately measuring battery health with on-board technologies.

Why does all of this matter?

Because an on-board SoH percentage, taken in isolation, is simply too coarse to protect either party in a used-EV transaction. For buyers, it offers no guarantee that the battery will deliver the range, longevity or performance implied. For retailers, relying on that single number carries financial and reputational exposure: customers who later experience curtailed range or performance can invoke consumer-protection law, and there are documented cases in which cars advertised at 100 % SoH were found to need full battery replacements—forcing the seller to repurchase the vehicle. Independent capacity testing and deeper BMS analytics are therefore no longer optional; they are the only reliable way to validate battery health and maintain customer trust.

What do the experts say?

Leading electrochemist and industry expert, Dr Euan McTurk, has expressed his concern over the reliance on on-board SoH figures: “The different approaches to SOH estimation taken by different vehicle brands makes it difficult to make an accurate comparison of SOH between different makes and models of EV. There is therefore a need for a standard, unifying SOH algorithm that provides an impartial and accurate estimation of SOH. Some SOH diagnostics firms claim to offer this with tests that take only a few seconds to complete. However, this instantaneous look at battery data doesn’t give us much meaningful data with which to accurately calculate its SOH.”

What should consumers be looking for instead?

Retrieving on-board SoH values via the OBD port is not a test, it's merely retrieving manufacturer supplied data from the car. Some of the additional BMS data that can be retrieved from the OBD port can be of value in assessing battery condition. For example, understanding the vehicle’s charging history and cell imbalance under load can highlight potential battery faults. As the Austrian test house, TUV, has outlined, the only way to properly conduct a battery health test is to either charge or discharge the battery. Excitation of the battery prompts a response that can be measured to understand key battery characteristics. This is crucial for generating reliable and accurate results.

The importance of Independent battery health testing

At ClearWatt we are setting a new benchmark for EV battery health in the retail, leasing, auction and consumer sectors. We pair advanced OBD scanning, capturing the full suite of Battery Management System indicators, not merely the onboard SoH figure—with an independent, charge and/ or discharge-based capacity test that follows the measurement principles laid out in UNECE GTR 22. By analysing both energy and driving data, we establish the battery’s true capacity and its real-world range.

This twin-track methodology lets us pinpoint cell-group faults, identify uneven degradation within the pack and quantify any loss of usable capacity. The findings are distilled into clear, comprehensive EV Health Reports that equip buyers, sellers and owners with the facts they need. Consumers deserve more than a single manufacturer-reported SoH number; ClearWatt delivers the deeper, evidence-based insight the market now demands.